The crushing unit is designed for crushing non-sticky, medium hard or hard

construction debris, construction waste, concrete and less abrasive natural

materials such as limestone, sandstone and similar materials with a pressure

strength of up to 200 MPa.

Material to be crushed is transported by a loader to the feeding hopper. The

hopper is equipped with a feeder with vibrators.

The crushing unit is a single-strut crusher with abrasion-resistant lined jaws,

equipped with mechanical or hydraulic positioning of the output opening of the

crusher.

The conveyor belt width is 650 mm.

The DRS 2×2 crusher is primarily intended for crushing non-sticky bituminous

mixtures with stone admixture, for example road surfaces, brickwork, wood and

other similar materials.

It requires an electrical current supply for its operation.

The material to be crushed is transported to the crusher by a belt conveyor.

Crushing is carried out by two pairs of rotors with wear-resistant steel

teeth.

The drive is a gearbox with a motor.

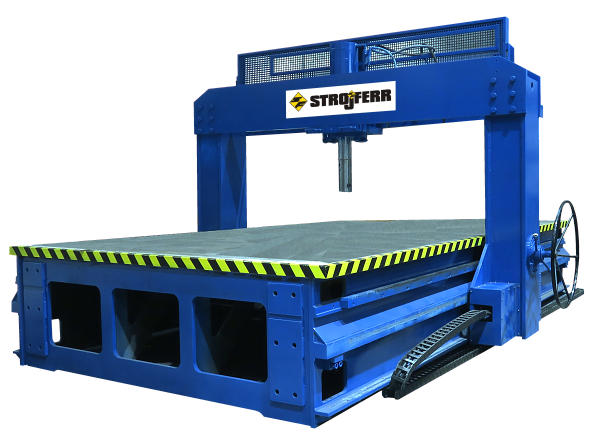

The straightening press is a technological device designed for straightening

weldments.

The drive of the ram is hydraulic. The transverse drive of the ram travel and

the drive of the longitudinal travel of the gantry on the leveling table is

manual.

The straightening table is designed as a modular system. The required table

length can be achieved by connecting several tables. The straightening table is

equipped with holes for mounting lifting rollers and a large hole at the edge of

the table for the possibility of pressing parts of cylindrical shapes.

We custom make machinery components based on the customer documentation.

We custom make welded components in a design and scope corresponding to the technological potentials of our plants and based on the customer requirements.

We produce shafts, flanges, pivots, wheels and cogwheels in the scope of our manufacturing potentials.

We produce wheels with internal and external spur gearing with straight and helical gear and grind the teeth in the scope of the technological potentials of our machinery.

We provide external services of our tool room section.